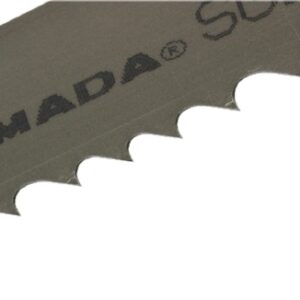

Bi-Metal Bandsaw Blades

Amada bi-metal bandsaw blades for low alloy steels, aluminium, carbon steel, stainless, tool, die & mould steels, structural steels, steel to 45 HRc, nickel alloys, non-ferrous metals.

All blades are made to order and shipped directly to suit your saw and application.

Amada bi-metal bandsaw blades consists of a high speed steel cutting edge made of M42 or M71 material welded to a flexible steel body material. The blade body material is optimised for long bending life whilst supporting the tip in the cut. The high speed steel tip is significantly harder than the body material and designed for long wear life and chipping resistance whilst cutting at faster speeds. The harder tooth makes bi-metal blades significantly tougher than standard carbon steel blade, and is suitable for general purpose cutting of steel, non-ferrous and non-metal materials in bundles, tube and solids and for cutting difficult materials such as stainless steel, nickel alloys and titanium.

Features

- M42 or M71 bi-metal tip material for toughness and wear resistance

- Variable angle geometry depending on tooth pitch for wide range of cut widths

- Special set patterns for a wide range of material sections to be cut

- Shock resistance to reduce chipping and tooth loss

- Multi-purpose tooth shapes for a variety of applications Designed for production and general purpose sawing

- Suitable for solids, bundles, tubes, profiles and castings