About Us

About Accurate Cutting Services Ltd

- Subcontract sawing services

- Bandsaw blade welding and supply of Amada bimetal and carbide tipped blades

- Circular saw blade sharpening and supply of Julia HSS and carbide blades

- Bandsaw machines from Amada, Pedrazzoli and Soitaab/Friggi

- Circular saw machines from Amada and Pedrazzoli

- Service, spares and repairs for most make of saws, and especially Amada, Pedrazzoli, Soitaab or Friggi.

“Accurate Cutting Services understands our needs and those of our customers”Andrew Nicoll, Business Development Manager, Callender Lancashire Aeropart Ltd.

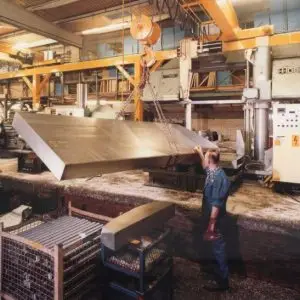

Offering the UK’s largest, most versatile sub-contract metal sawing service

“Accurate Cutting Services has proved itself very flexible and quick to respond to sudden changes in our production programme”Ian Young, Managing Director, Stokes Forgings Ltd.

Its sectioning of part-finished or finished forgings, fabrications and castings brings benefits such as low material loss, nil distortion and improved accuracy. Manufacturing processes are simplified, with reduced production times and lowered direct costs.

Doncaster FVC’s case book of advanced applications includes sawing, in two, a centrifugally-cast turbine generator casing, 1350mm long, 1450mm in diameter and with 200mm thick walls, using what is one of the UK’s largest horizontal band saws.

It produces high volume rounds, squares, solid bars and tubes, also, to close tolerance, in ferrous and non-ferrous metals. One object for such precise cutting was a multiport extrusion, demanding minimal distortion.

“The casing is for Siemens Industrial Turbomachinery AB, and without the assistance of Accurate Cutting Services it would have been a struggle to find a subcontractor with the knowledge and capacity to cut such a large casing”Keith Winkley, Doncasters FVC Ltd

Adding more value – by working near to its customers

The company’s responsiveness to industry’s needs has led to it establishing working cells in Lancashire, Yorkshire, West Midlands and a second Redditch location. Some are within customers’ own premises, reducing WIP and transport costs and optimising response-to-change times.

Its services bring the greatest possible value to the customers there. Lead times and costs are low in the JIT working, and communications are ideal.

Advanced investigation and value-recovery services

Solutions, too, through sawing-machine and blade sales and service

Accurate Cutting Services applies its 50 years experience of developing, manufacturing and using band and circular saw blades, and machines, to providing sales and support solutions to their users.

With the metals used in today’s manufacturing including advanced alloys with extreme thermal, chemical or mechanical properties, heavy demands are made of blades. The right choice of blade to use, and its proper maintenance, are vital if delivery times, productivity targets and quality standards are to be met.

To provide the best possible service responsiveness, the company’s blade manufacture, grinding and repair, and sawing-machine repair work, are carried on around the clock.