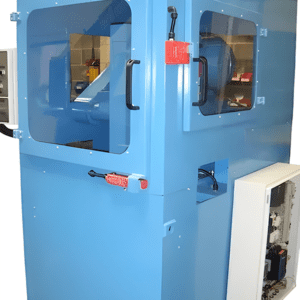

Cutmaster abrasive cutting machines BC 24/60

Metal cutting operations using abrasive discs are most commonly found where speed of cut, and good surface finish of the cut face are important.

The difference is even more marked when working with:

- Very hard or difficult to cut materials

- Heat sensitive materials

- Modern, sophisticated alloys

Description

Cutmaster has over 44 years of experience in the manufacture and supply of machines for various types of cutting-off operations. It is for this reason that Birkett Cutmaster can give a balanced view of suitable applications for abrasive cutting-off. The Special Benefits:

- Speed of cut, especially on solid sections

- Low heat generation on heat sensitive materials

- Cuts exotic alloys more effectively than traditional sawing methods

- Versatile in cutting a range of unusual component sections and shapes

- Foundry applications are catered for – specially designed machines are suitable for numerous cutting operations Which metals may be effectively cut?

Cutmaster machines are specifically designed to cut those metals and component types where the technology unquestionably gives the best results. Whilst this is not an exhaustible list, materials of which this can normally be said include:

- High chromium manganese alloy steels

- High speed steels

- High nickel alloys

- Nimonic alloys

- Tool steels

- Stainless steels

- Low alloy steels

- Titanium alloys

- Case hardened steel Cutmaster Capability

See also the smaller BC 20/20 abrasive cutting machine

Birkett Cutmaster is a UK designer, manufacturer and distributor of machine tools that provide flexible, safe and environmentally acceptable working practices. The range can meet virtually any requirement involving sawing and abrasive cutting.

- Abrasive wet and dry cutting off machines

- Special purpose cutting

This across-the-board expertise gives you the assurance that abrasive cutting off will only be recommended if it suits your needs best. And if the technology is suitable, the Cutmaster range of ACO machines will meet virtually all requirements.

Tailored Solutions Cutmaster would be pleased to advise on the number and type of machines necessary to meet different volume, batch or one off requirements. If necessary, complete manufacturing cells can be specified, to provide a variety of practical solutions. Machines can be supplied in manual, semi-automatic or fully-automatic modes. Birkett Cutmaster has extensive experience in supplying machines for the following general application areas:

- Production processes in volume

- Foundry applications

- Laboratory analysis Other Important Considerations

- Through their many built in features and their suitability for combining with ancillary equipment, the modern Cutmaster machines provide further reasons for adopting abrasive cut off technology.

- Safety for the operator by mechanical and electrical guard systems

- Environmental and workplace advantages from features such as dust control and noise attenuation.

- Ergonomic advantages from tailored loading and unloading equipment and work piece handling devices.

- Precision control of clamping, drives, feed rates and other semi-automatic and fully automatic features.

- Programmable machines for variable batch sizes, component dimensions and other parameters.

- Floor-to-floor times minimised by efficient methods of abrasive disc replacement and other tooling changeovers.

- Constraints on working layout

- The processing of special materials

- The handling of volume components, often as part of process flow-lines.

- The need to cut large or awkward profiles or sections

If required, Cutmaster will carry out a full audit of your cutting needs in order to arrive at the most suitable machine for the job, plus necessary ancillary equipment such as dust extractors. Seeing through the installation: Our highly experienced engineers are involved in all aspects of the installation and commissioning. Remembering the after-care: In addition to any maintenance needs, Cutmaster can advise on supply of consumables such as discs, coolants and oils.