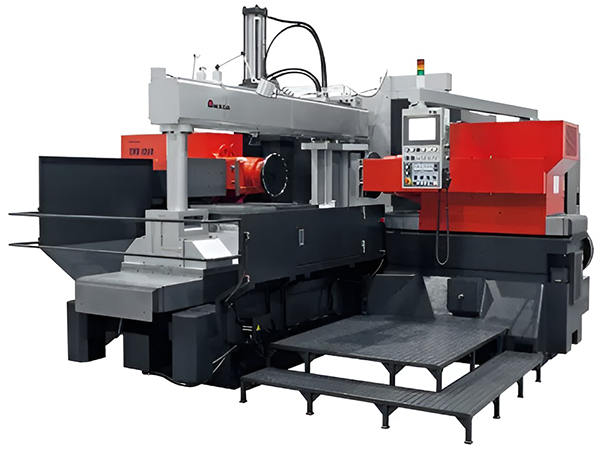

Amada THV1000 Double Headed Milling Machine

![]()

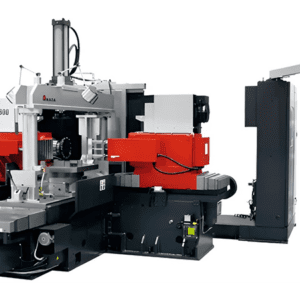

The Amada THV1000 is a highly productive duplex milling machine for high-quality machining of sheet material in the size range 1,000 x 1,000mm and a maximum height of 400mm.

Description

The fully automatic machining of all four surfaces without reclamping of the material results in high angular accuracy and parallelism. To complement their range of metal cutting machinery, Amada have launched a unique Twin Headed Milling Machine – claimed to operate much faster than conventional vertical milling machines and machining centres, whilst providing improved accuracy and substantial cost savings.

Amada THV Series milling machines are used to mill the steel blanks cut by Amada Pulse Bandsaws, to produce accurate, high quality machined surfaces for the next stage of manufacture. They have also proved to be particularly effective when used in conjunction with other high precision Amada milling and grinding machines, thus maintaining quality and speeding production rates over a wide range of products. When milling four sides of a work-piece, conventional systems machine all four surfaces, one-by-one, whilst the operator is required to man the machine through four set-up procedures.

THV series mill platform THV series mill cutter THV series mill clamping and measuring THV series mill machiningTHV series mill machining sequence THV series mill finished machined block

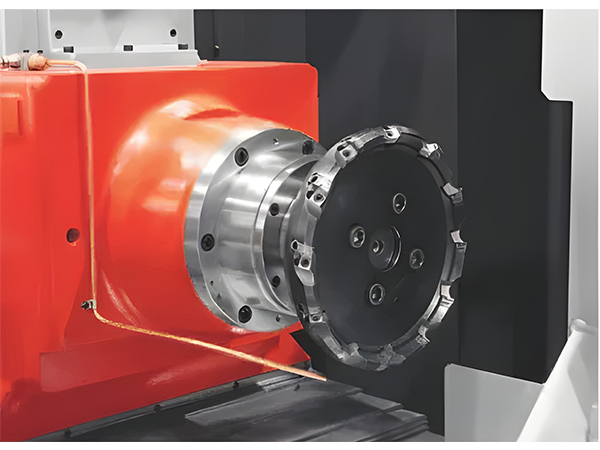

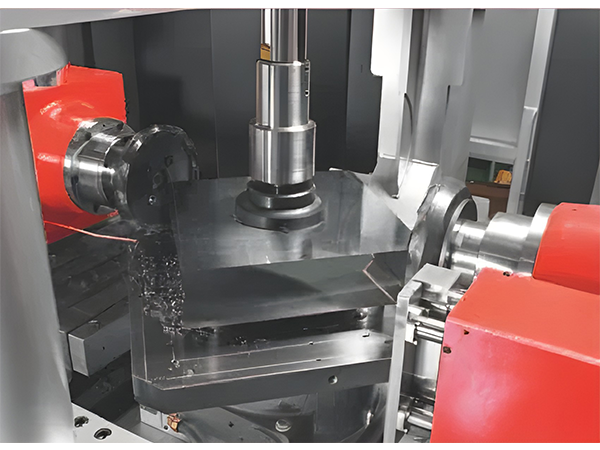

By contrast, the Amada THV double headed milling machine is a more automated process, operating with two cutters, which machine two sides of the work-piece in a single operation. The operator makes a single work setting, starts the machine and is able to attend to other duties – making a significant saving on the cost of manpower.

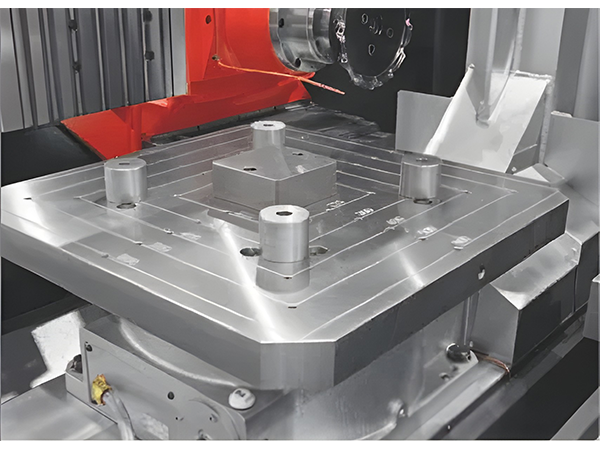

To provide improved accuracy, the Amada THV Series Machine incorporates a positioning device that automatically calculates and moves the work-piece to the correct position on the work-table, whilst an automatic centring system measures the size of the work-piece and calculates the exact centre. Even if the work-piece is not set on centre, the twin cutters will move to suitable positions and cut the same depth.

Operation

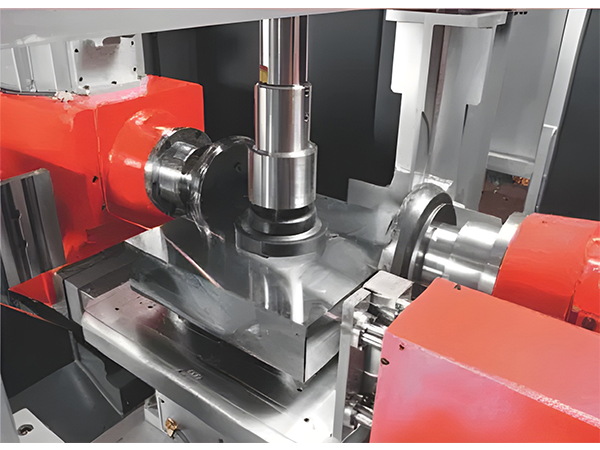

In operation, the top and bottom surfaces of the clamped work-piece are automatically milled by two cutters in a simultaneous operation. After milling the first two surfaces, the system automatically indexes the work-table, rotating it through 90 degrees to mill the remaining two surfaces, with no operator intervention.

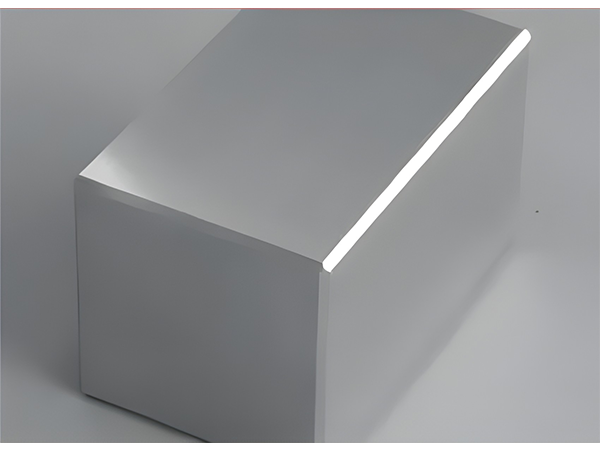

In a comparison of milling times, when machining four sides of a 150mm cube, an Amada THV twin headed machine requires only one set-up and completes the operation in four minutes. A conventional vertical milling machine requires four set-ups and takes twenty minutes to complete. When comparing the total time taken, including machining times and set-ups for high accuracy, the vertical milling machine takes approximately one and a half hours to complete the process, whilst the Amada twin headed machine requires no more than ten minutes.

To provide improved accuracy, the Amada THV Series Machine incorporates a positioning device that automatically calculates and moves the work-piece to the correct position on the work-table, whilst an automatic centring system measures the size of the work-piece and calculates the exact centre. Even if the work-piece is not set on centre, the twin cutters will move to suitable positions and cut the same depth.