50 years of experience sawing metal

Cutting Services

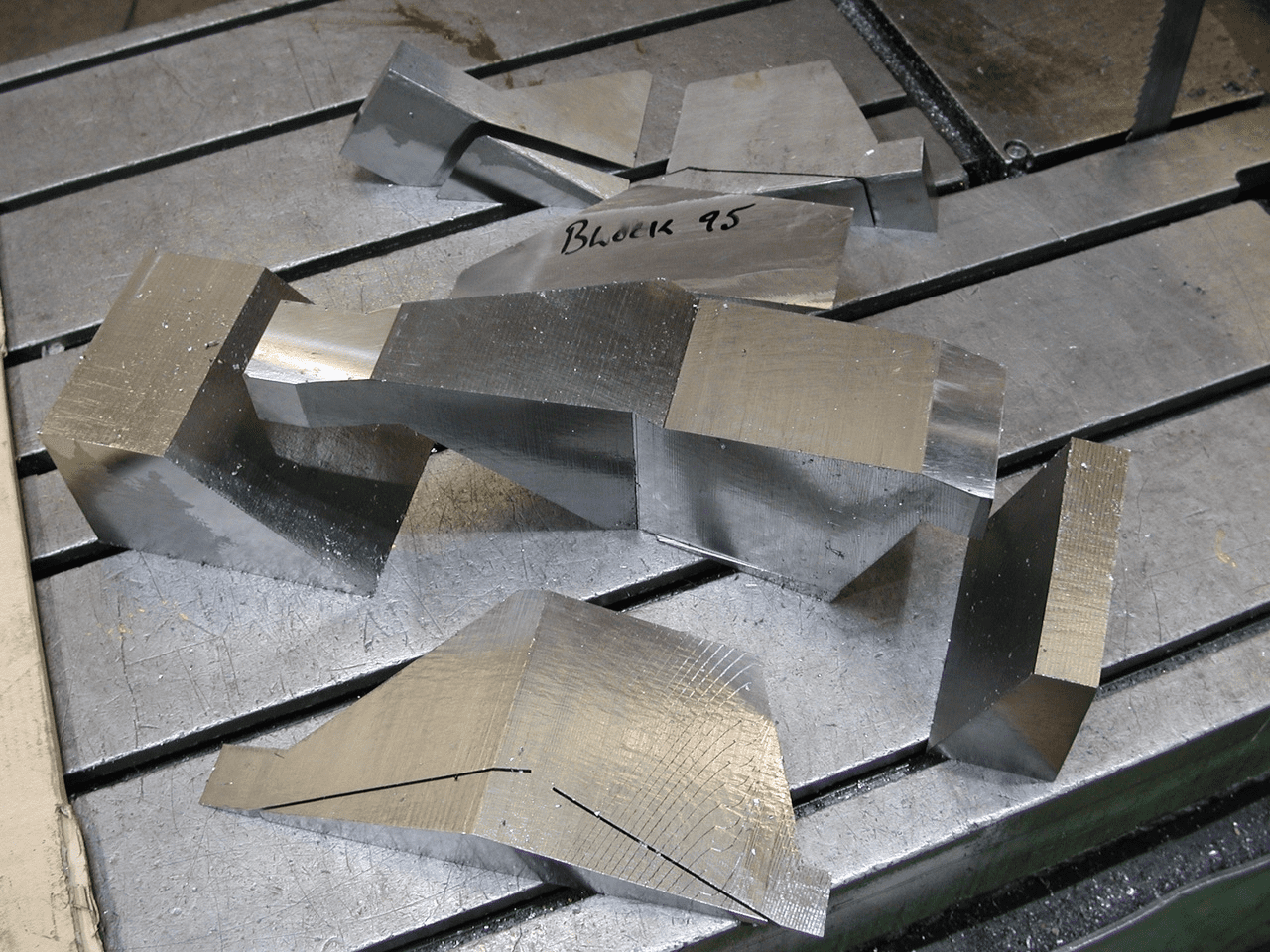

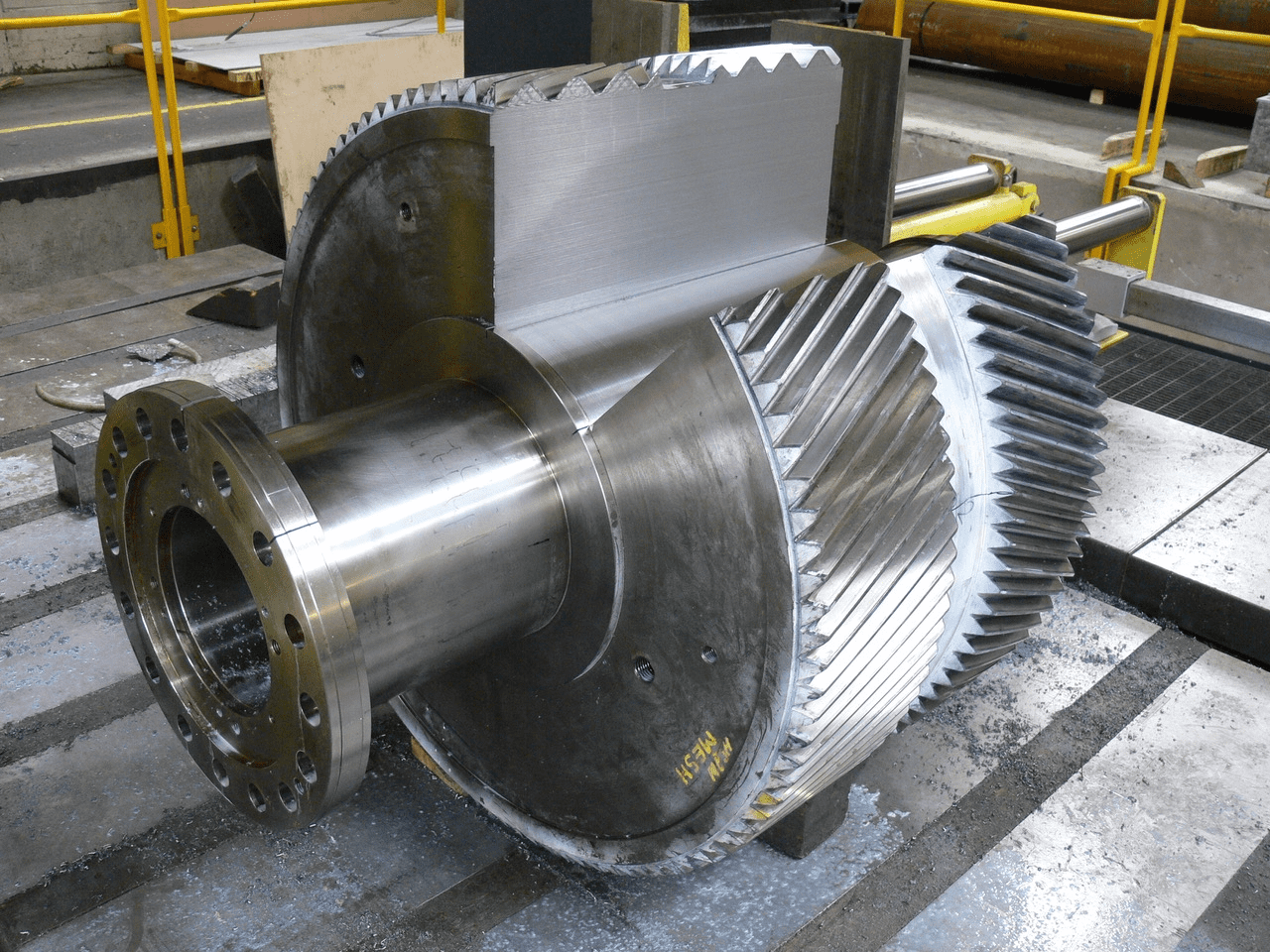

Profiling and sectioning

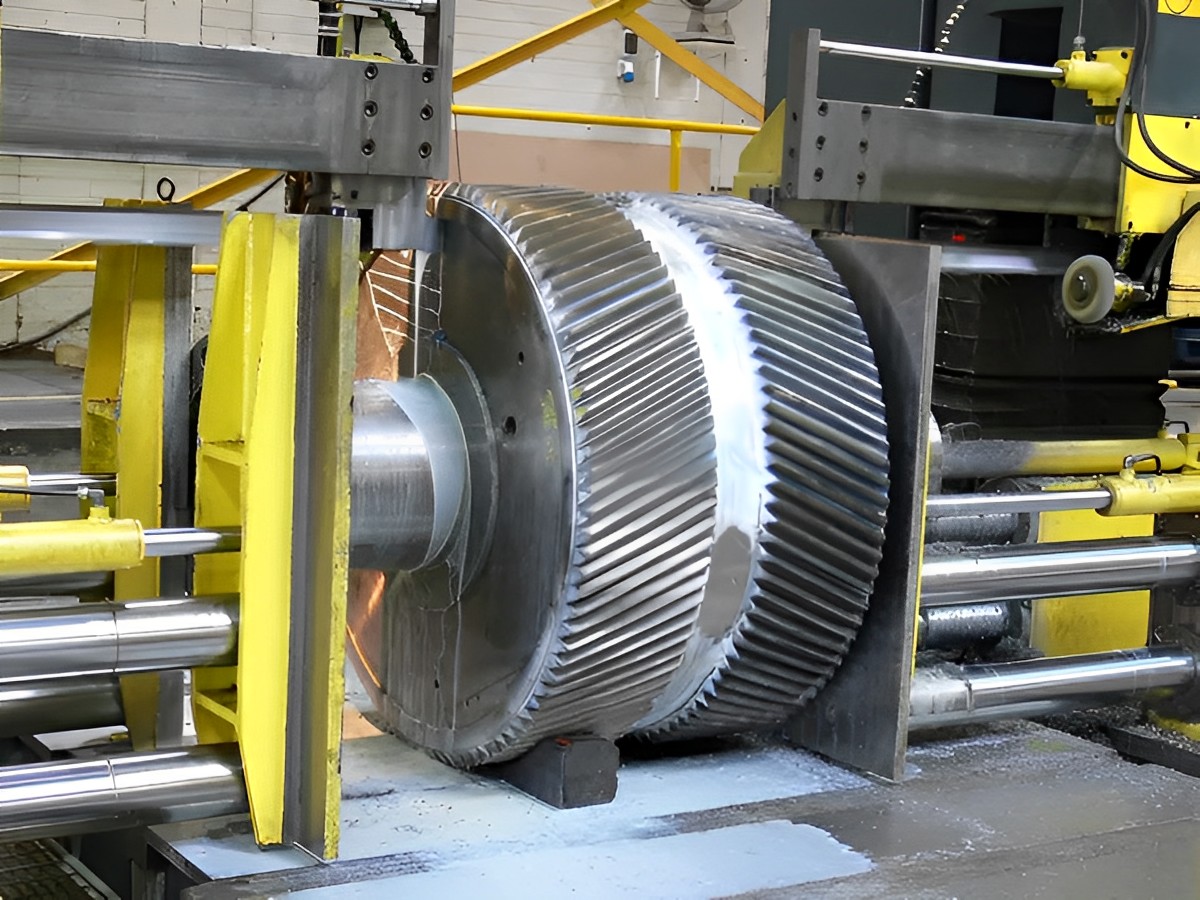

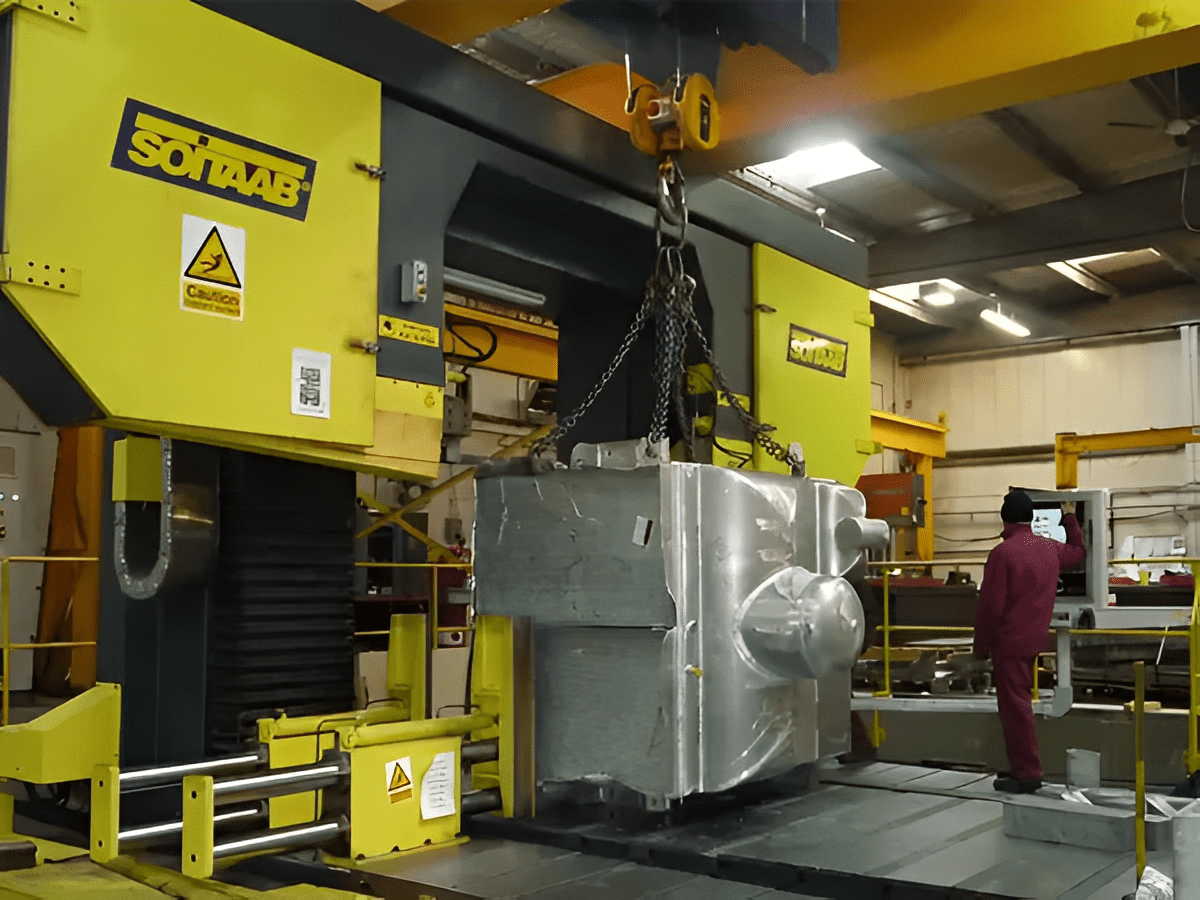

Large sawing capacity

Bandsawing to remove excess material

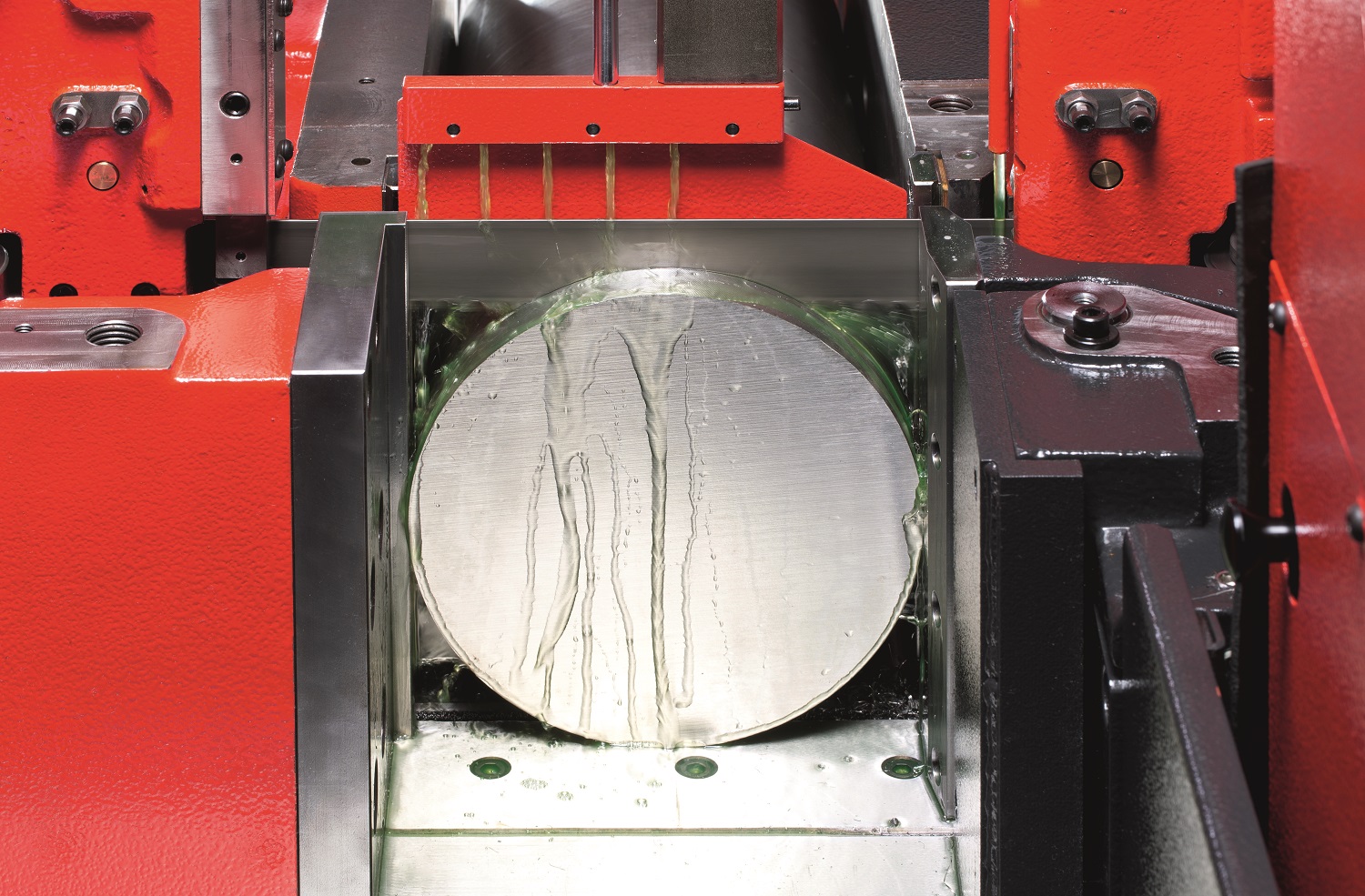

Precision metal cutting service

Reclamation and failure investigation using saws

Special cutting applications for saws

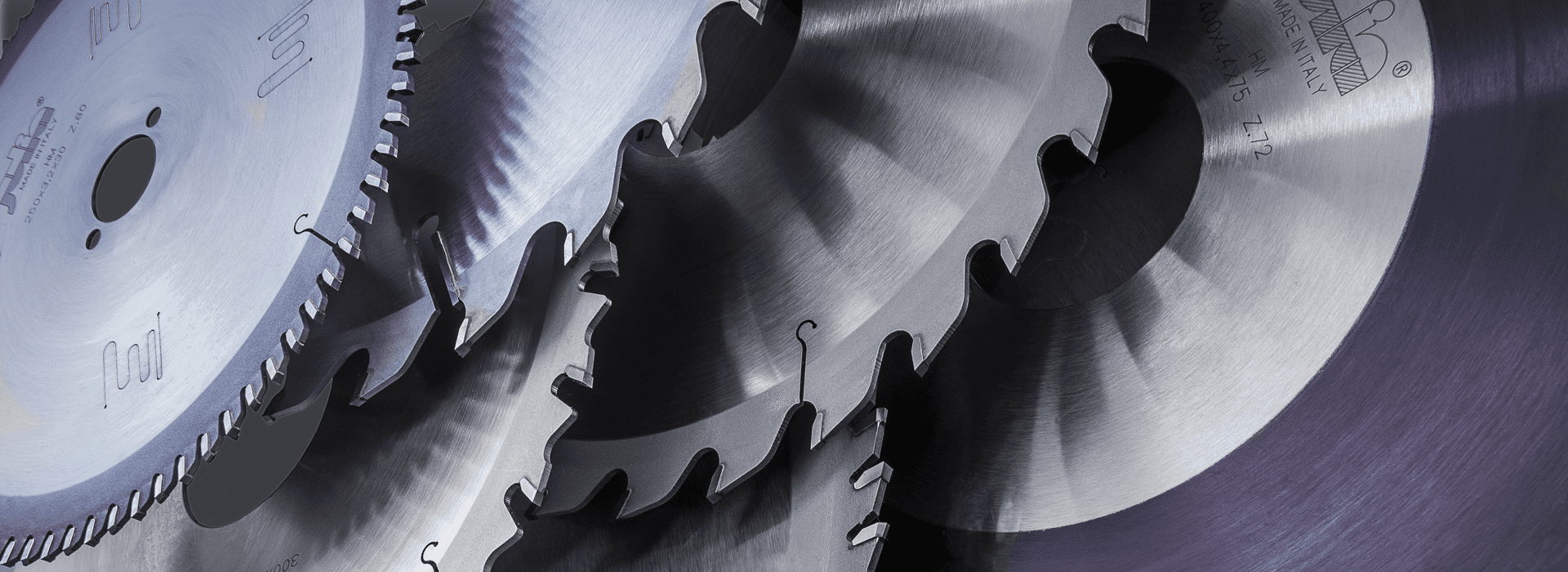

Blades

Bi-Metal Bandsaw Blades

Carbide Bandsaw Blades

Carbide Tipped Circular Saw Blades

HSS Saw Blades

Machines

Abrasive Cut-Off Machines

Bandsaw Machines

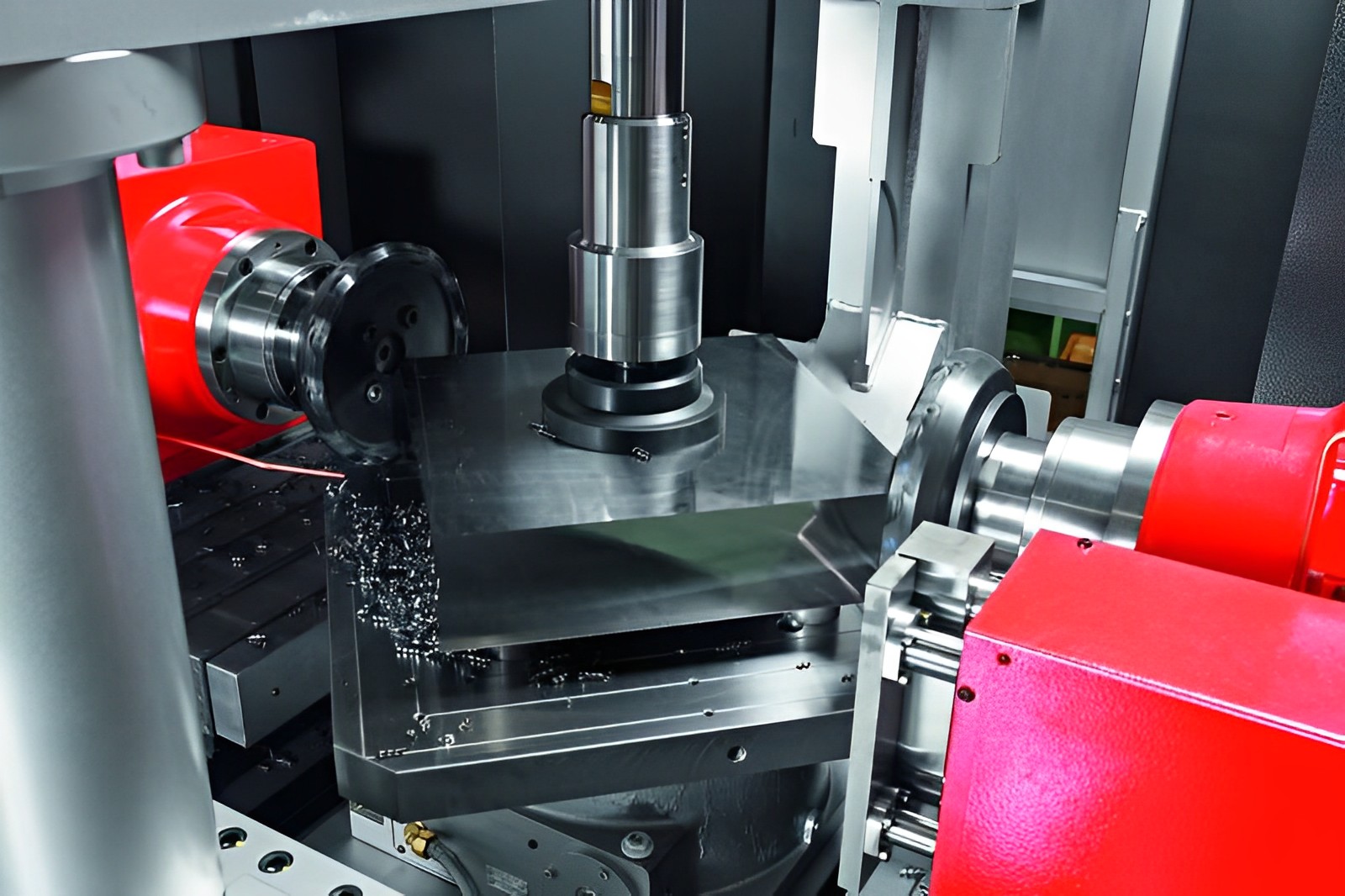

Circular Saw Machines

Milling Machines

Used Bandsaws

ABOUT US

Our Quality Accreditation

Quality accreditation approvals EN 9100:2018 and ISO 9001:2015 The quality accreditation includes a system to provide lot traceability to raw materials/components operating within a Quality Management System, which complies with the requirements of pr EN9100:2016 (technically equivalent to AS9100D and JISQ 9100:2016) and ISO 9001:2015 and is assessed in accordance with EN 9104-001:2013.

Mitre and angle cutting capacity up to 2000mm (78″) round or square. Maximum weight limit 25 tonnes.