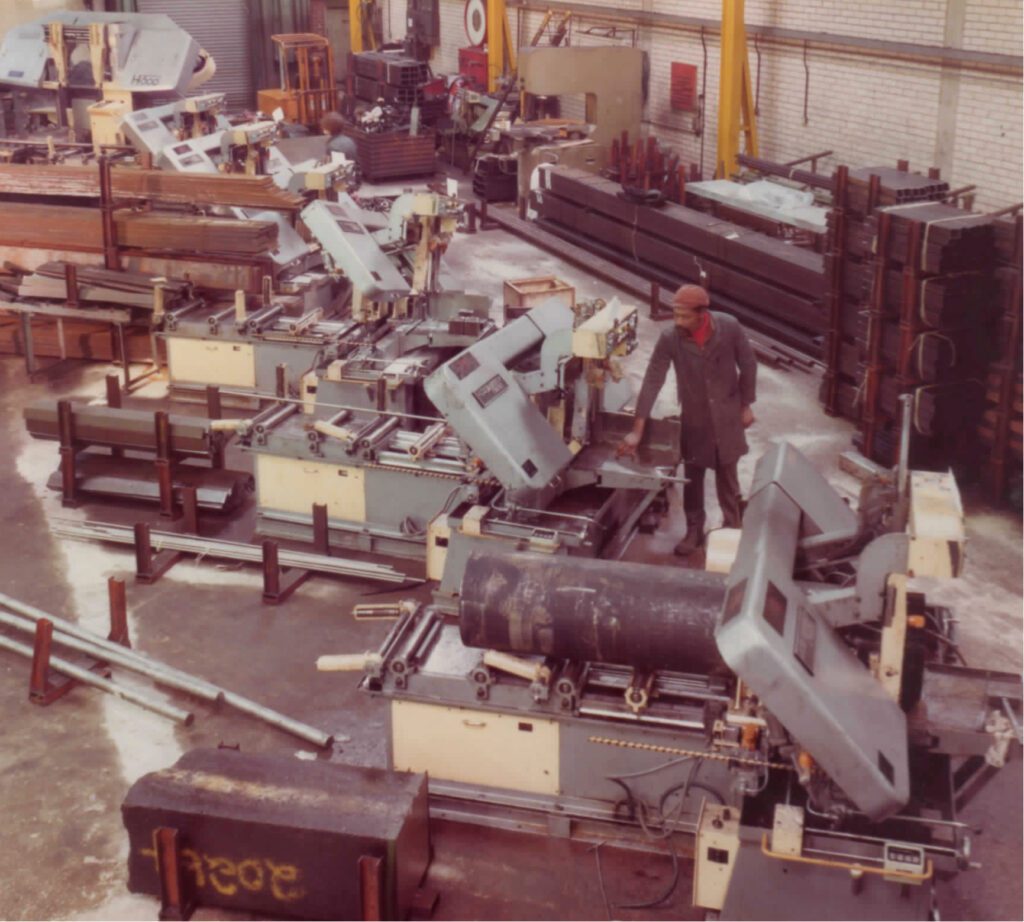

Pedrazzoli SN 420 MRM manual mitre bandsaw

Description

MAIN FEATURES

All main machine components are in cast iron. Very robust structure reduces noise level and vibrations during cutting cycle.

- Motor is in vertical position to reduce dimensions at rear, the transmission is made by means of a worm drive gearbox in oil bath (1:40 ratio).

- Large circular support base: it offers an ample surface to support piece during cutting cycle and allows to reach a high grade of precision in cutting perpendicularity. It rotates over a tempered ball track giving maximum smoothness during rotation.

- Adjustable bow position by means of a key on eccentric bushing for 90° cuts, by means of mechanical stops at 45° right & 45-60° left.

- Blade guides: they drive the blade sliding by means of widia hard metal plaques with bearings on eccentric bushings.

- Adjustable manual vice. It can be positioned lengthwise along the entire machine base. Vice features: rapid closing, closing hand wheel, flat adjustable gib plate.

- Retractable and adjustable vice shoulders. Pushing back the retractable vice shoulder, it is possible to reach the maximum cutting capacity (420 x 190 mm, at 90°). The adjustable vice shoulder allow always to obtain a precise alignment.

- Blade tightening device: this is the best solution for a constant and uniform blade tension.

- Blade lubrication cooling system with electric pump and two adjustable taps placed on blade guides.

- Control panel located in an easily accessible position with ON/OFF switch, cutting speed selector (2 speeds), MANUAL/DYNAMIC cutting selector (for machines with Newton device), emergency push button to cut off the power to the motor in case of emergency.

- Blade start switch with “man present” guard. The safety switch for blade drive is guarded by a cover against accidental start-up. It works in low voltage.

- The hinged bow is moved on a support with conical bearings.

ACCESSORIES UPON REQUEST:

- Micromist lubrication

- MRP pneumatic quick clamp kit

- Laser cutting indicator

- Mechanical speed variator

- Loading & unloading conveyors

DIMENSIONS > 870 x 1860 x 2100 mm

WORKTOP HEIGHT > 955 mm

WEIGHT > 550 kg

Cutting capacity

> Round tubes

45° sx: 170 mm

0: 280 mm

45° dx: 230 mm

60°: 150 mm

> Square profiles

45° sx: 150 mm

0: 270 mm

45° dx: 220 mm

60°: 150 mm

> Rectangular profiles

45° sx: 240 x 90 mm

0: 420 x 190 mm

45° dx: 230 x 150 mm

60°: 140 x 220 mm