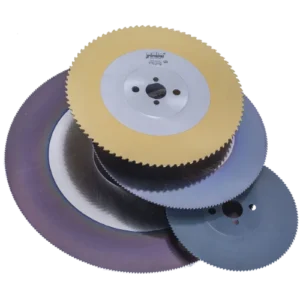

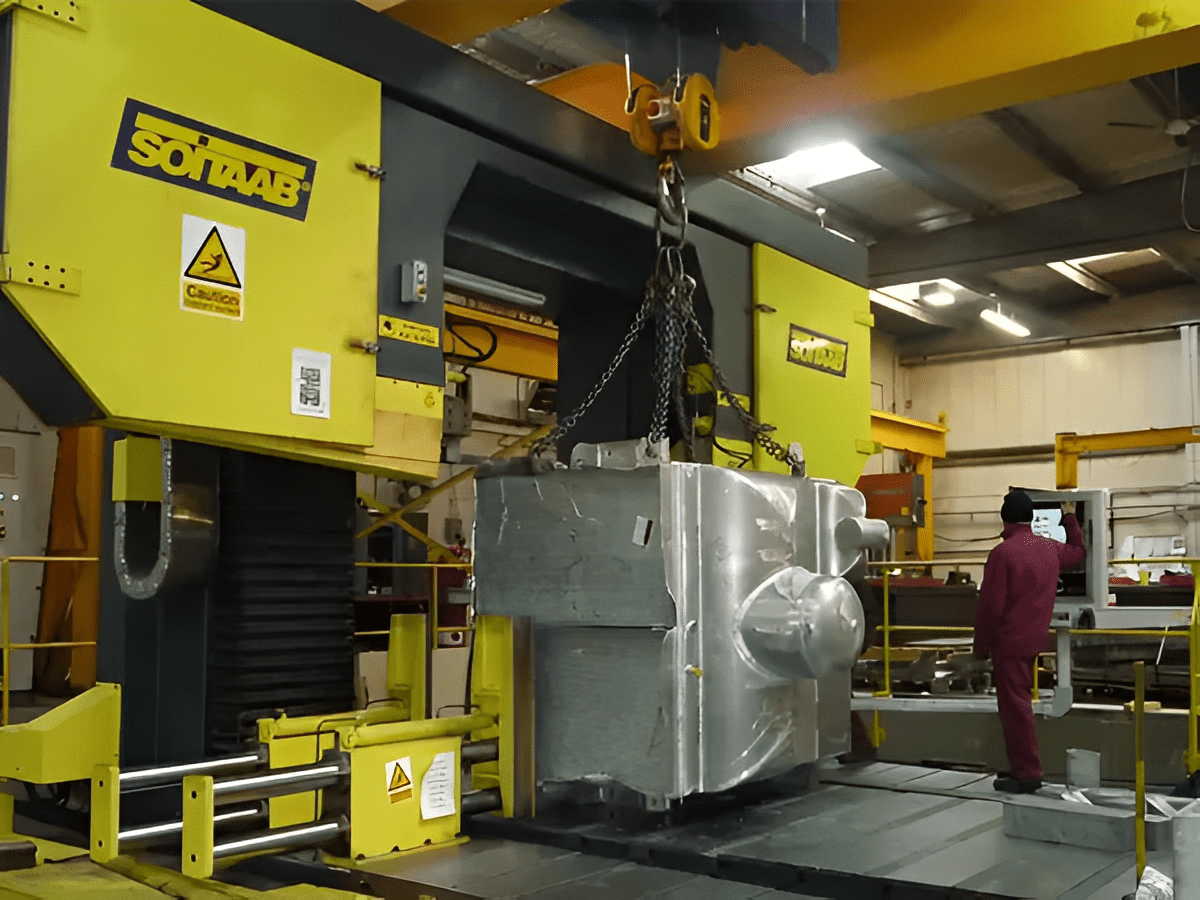

Reclamation and failure investigation using saws

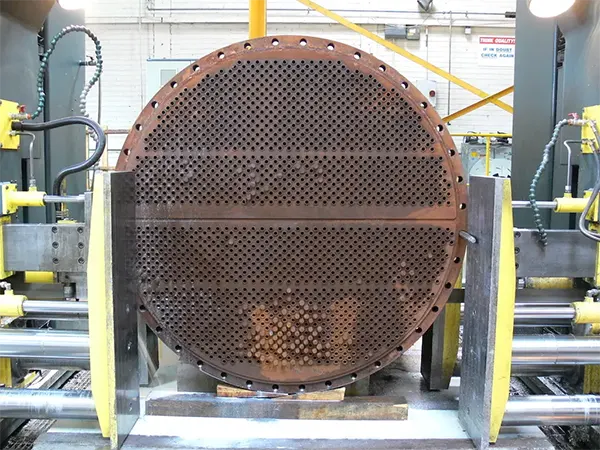

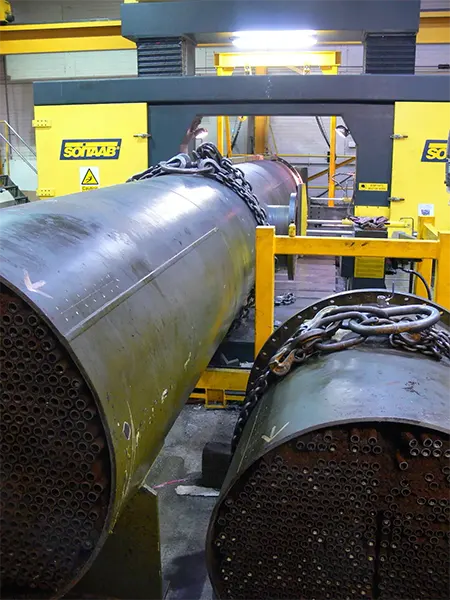

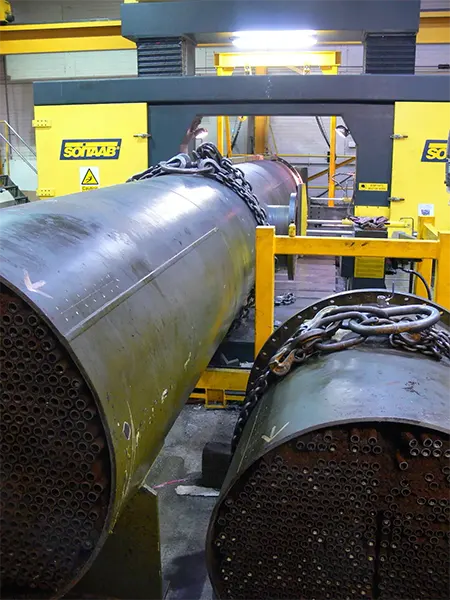

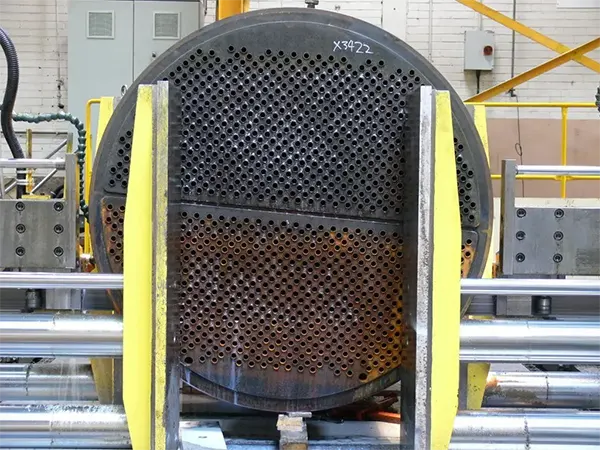

Recovering end plates from heat exchangers

The end plates of heat exchangers are often one of the more expensive parts of the fabrication, and during tube replacement extracting the end plates for reuse during the re-tubing process.

The end plates have many hundreds of tight tolerance holes drilled, designed for a fit with the tubes. Once the casing is removed, and the end plate sawn off the tubestack, replacement tubes can be installed and the outer casing re-fitted.