Precision Metal Cutting Solutions for British Manufacturing

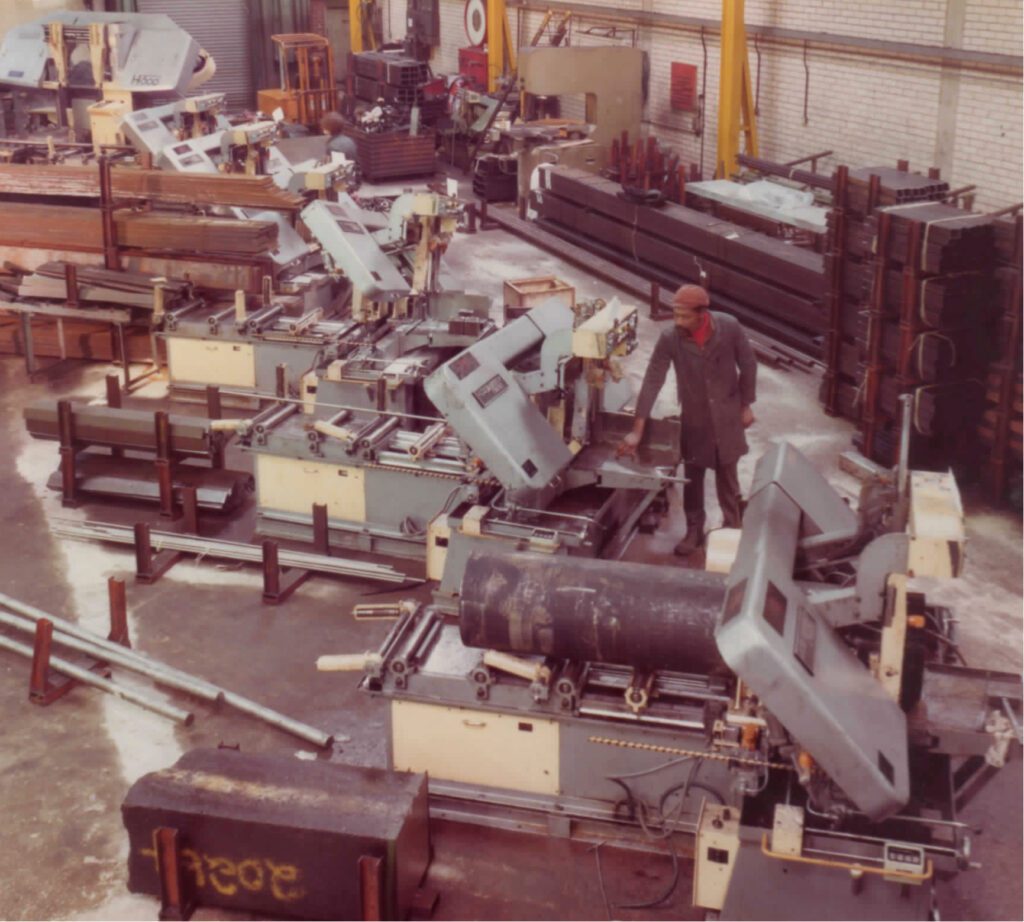

Over 55 Years of Expertise in Subcontract Sawing and Specialist Cutting

What does Accurate Cutting Services do?

How We Support UK Manufacturers

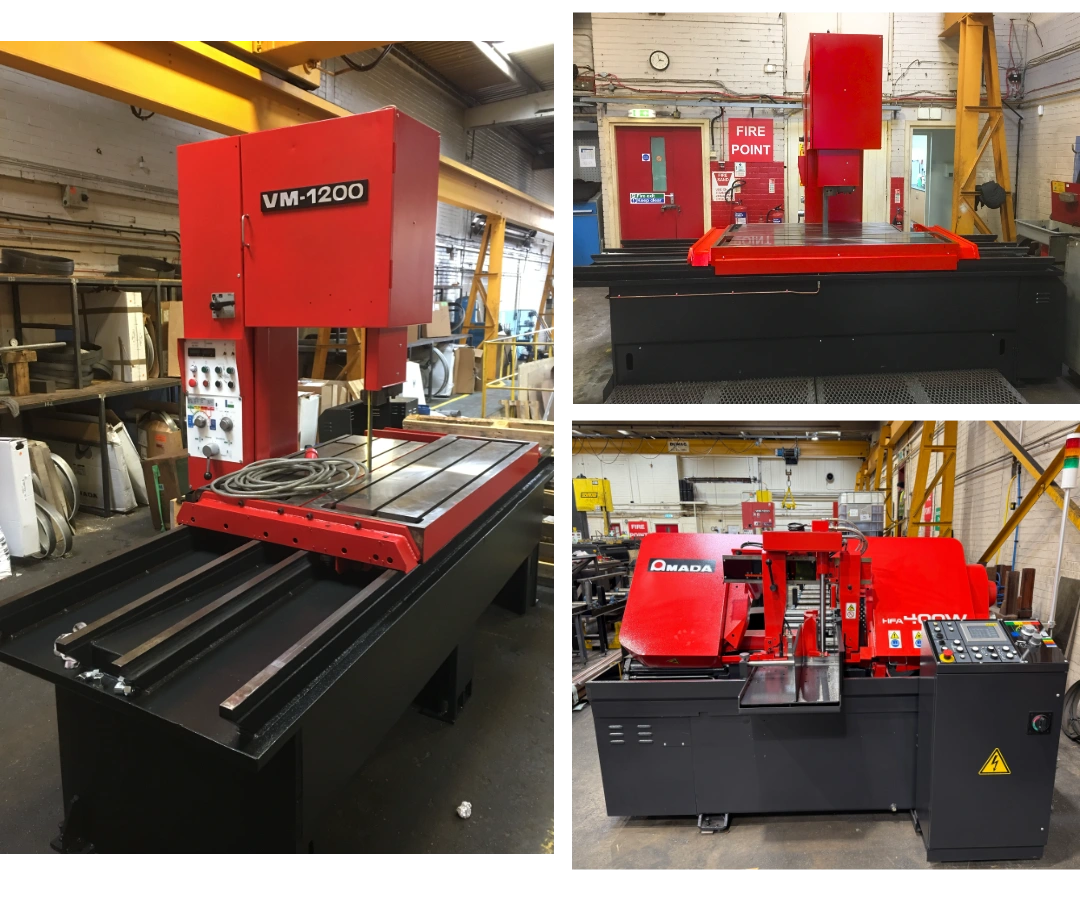

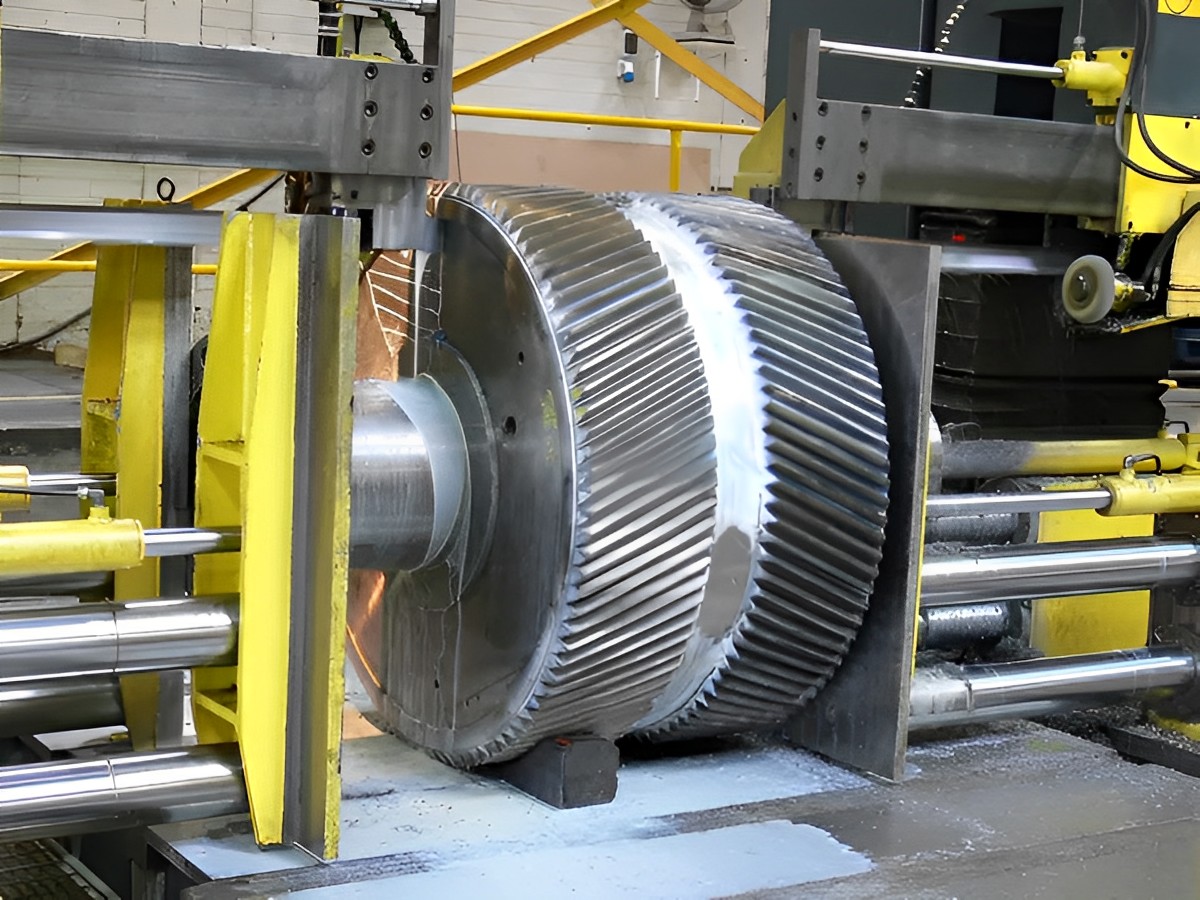

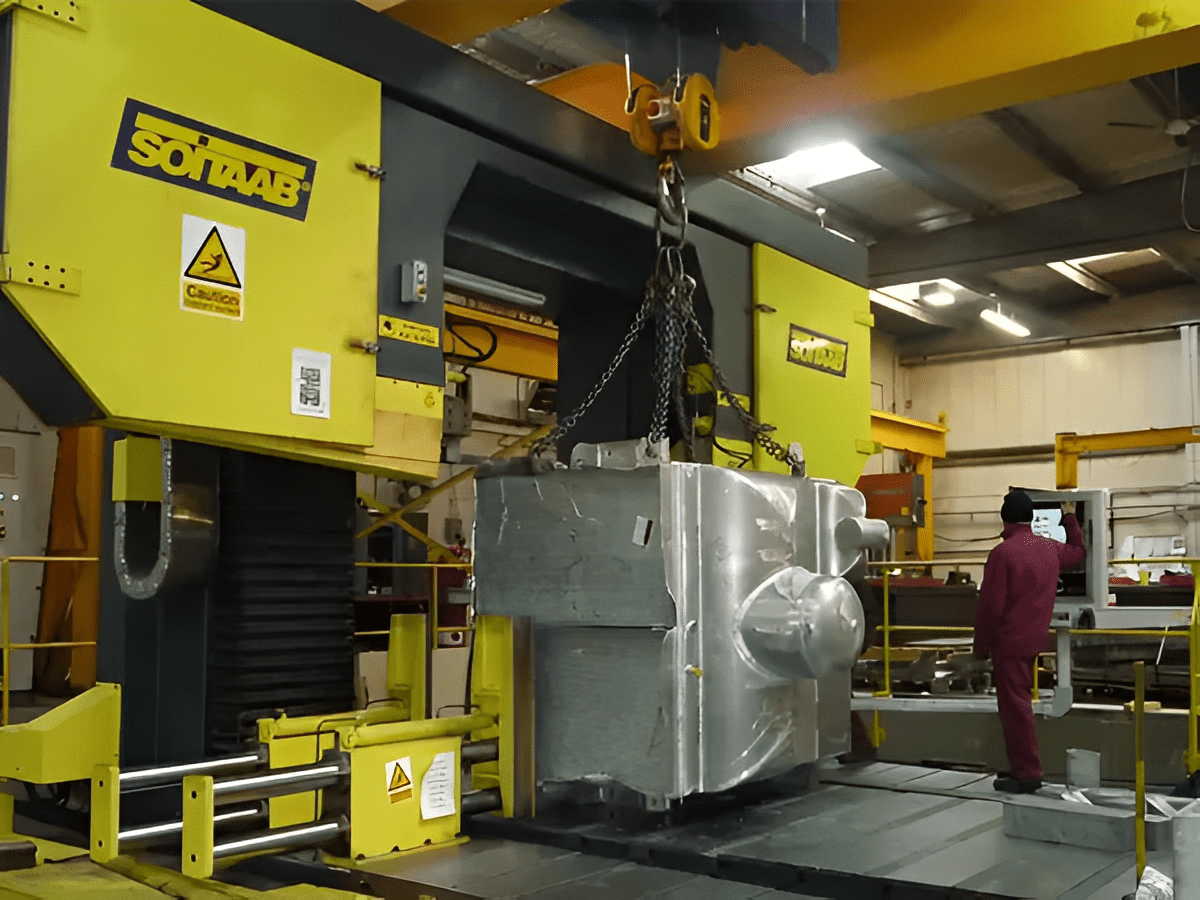

Our subcontract sawing division now operates 19 heavy-duty bandsaws, including new vertical and fully automatic machines capable of handling loads up to 25 tonnes.

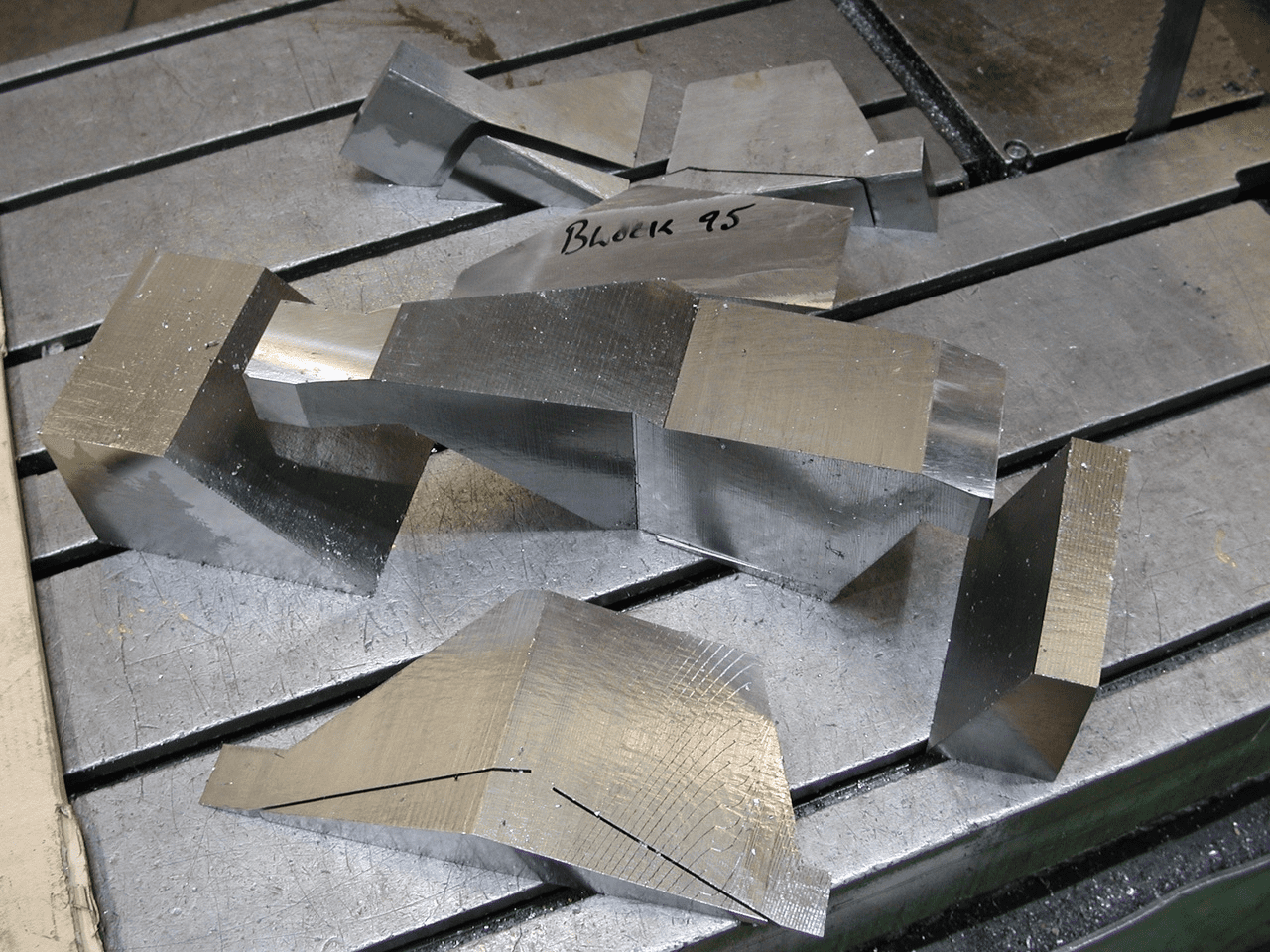

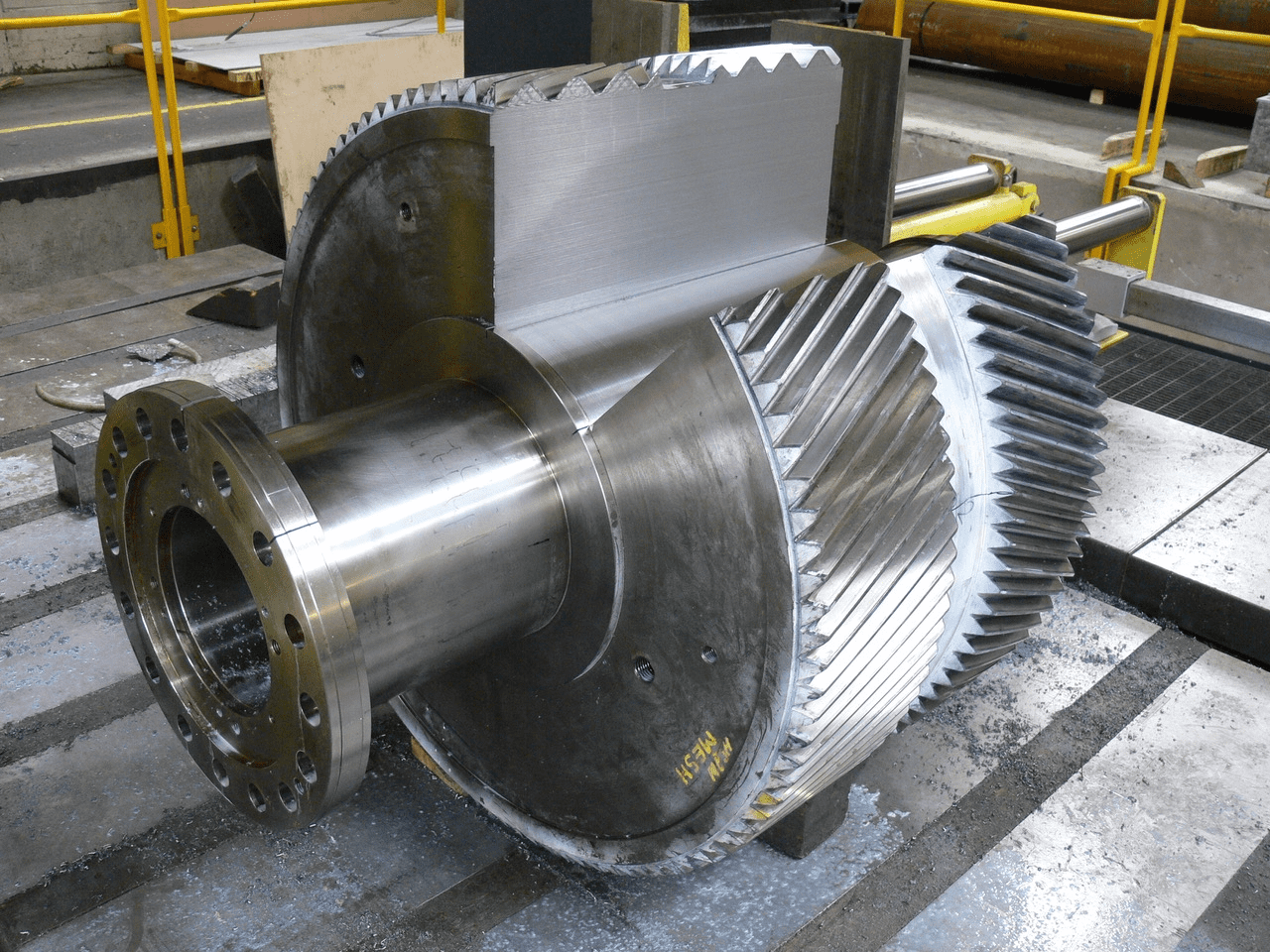

This expanded capacity allows us to process billets, bars, rings, plates, castings, and forgings — all with faster lead times and exceptional dimensional accuracy.

What Makes Our Cutting Capabilities Unique

-

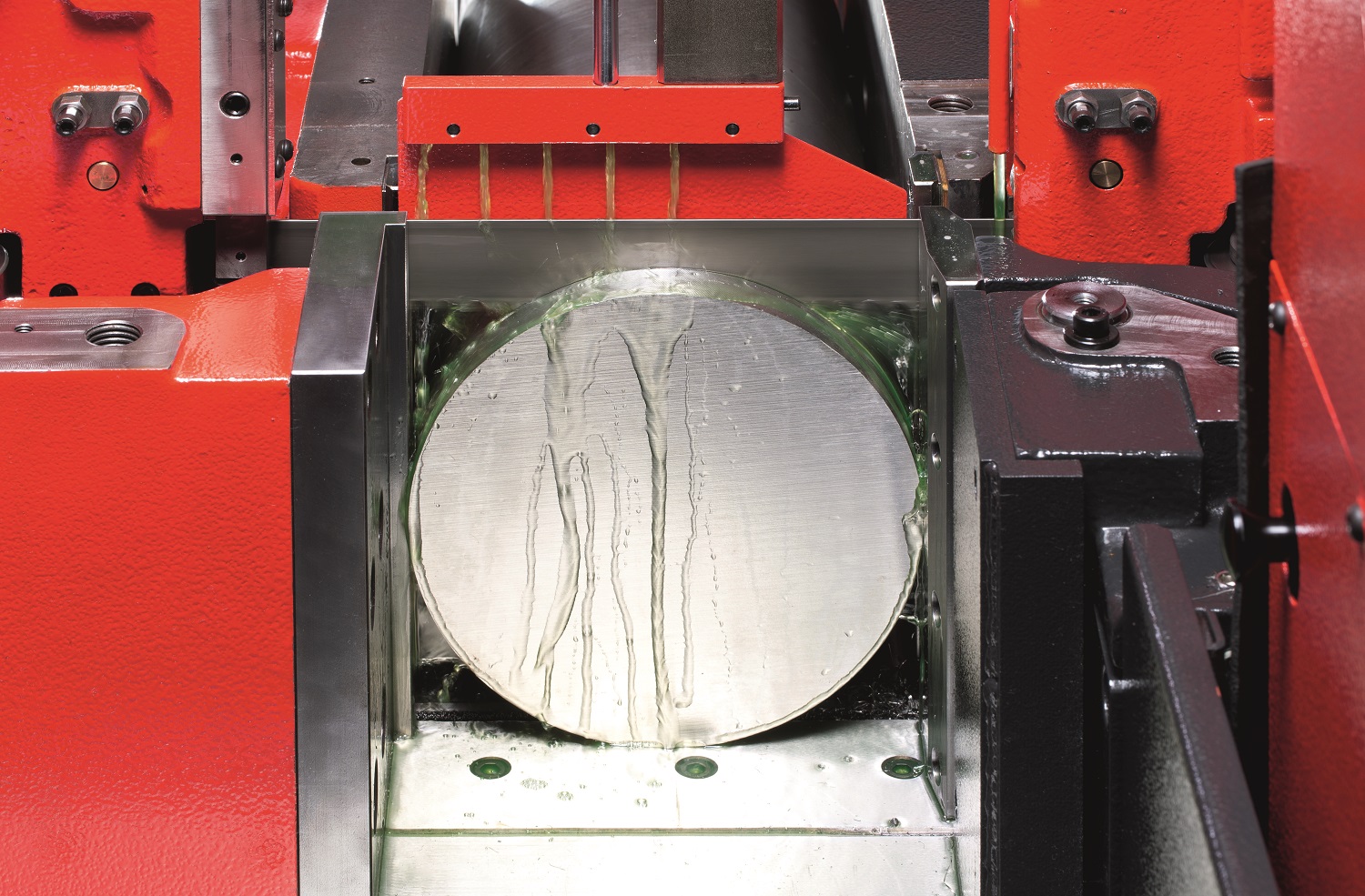

High-performance sawing technology for close-tolerance and large-section cutting.

-

Precision billet and bar sawing with 400-class automatic bandsaws.

-

Specialist large-scale sectioning, including complex materials and components up to 1,500 mm diameter.

-

Failure investigation and reclamation cutting services for engineering and fabrication clients.

Even with the saw maximum capacities, we can often cut larger items depending on the particular cut to be achieved – contact our cutting office to discuss your requirement.

Proven Expertise in Complex Materials

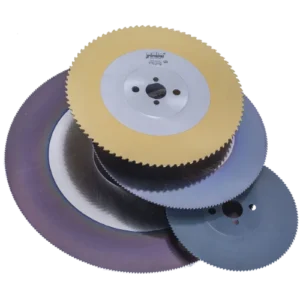

From advanced alloys to titanium and high-strength steels, we select the right blade, feed, and cutting strategy to ensure quality, productivity, and safety.

Our engineers have successfully dry-cut components for the petrochemical and nuclear sectors, including the Health & Safety Commission reactor-vessel project — where no other UK company could perform the job.

Why Choose Accurate Cutting Services

-

Over 55 years of trusted experience.

-

Nationwide subcontract sawing with rapid turnaround.

-

Capability to cut up to 25 tonne components.

-

Skilled team using 19 industrial bandsaws for high-precision, heavy-duty work.

-

Specialists in cutting difficult metals used in today’s advanced manufacturing.

Cutting Services

Profiling and sectioning

Large sawing capacity

Bandsawing to remove excess material

Precision metal cutting service

Reclamation and failure investigation using saws

Special cutting applications for saws

ABOUT US

Our Quality Accreditation

Quality accreditation approvals EN 9100:2018 and ISO 9001:2015 The quality accreditation includes a system to provide lot traceability to raw materials/components operating within a Quality Management System, which complies with the requirements of pr EN9100:2016 (technically equivalent to AS9100D and JISQ 9100:2016) and ISO 9001:2015 and is assessed in accordance with EN 9104-001:2013.

Mitre and angle cutting capacity up to 2000mm (78″) round or square. Maximum weight limit 25 tonnes.

Contact us about your cutting issues and how we can help.